DHZ Fitness Production In China.

Our philosophy is your advantage.

DHZ Fitness was founded in 2002 and is still owned by the founder. Due to his tireless passionate efforts, the company is the No. 1 manufacturer of professional fitness equipment in China.

DHZ Fitness aims to deliver exactly the right equipment for every project, in high quality and at the best price. To achieve this goal, DHZ produces over 95% of all components in its own factory. This is done using modern and efficient mass production methods such as laser cutting and robotic welding.

The resulting simplified quality assurance and control – together with the elimination of profit margins for suppliers – lead to lower production costs and a price advantage for DHZ customers.

Features of our production.

QUALITY

We place the highest value on quality in our production. DHZ Fitness is proud to be one of the top manufacturers in the world.

DEVELOPMENT

Our development department works with the latest CAD software to constantly expand and improve our product range.

TEST LABORATORY

Our ISO 9001 quality management system requires regular testing by our in-house laboratory.

ASSEMBLY

Final assembly is carried out on belts. Accessories such as screws etc. are pre-assembled.

LASER CUTTING

We work with CNC lasers to produce the three-dimensional frame parts and panels precisely and to place holes for bushings with pinpoint accuracy.

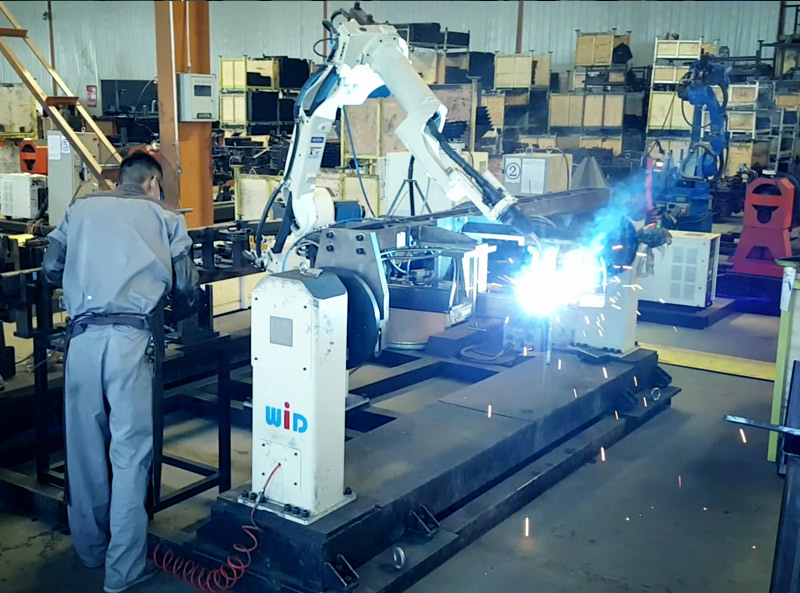

ROBOT WELDING

Robots are precise, produce clean, even weld seams and don’t forget anything.

SANDBLASTING & PHOSPHORIC ACID BATH

For prevention and rust removal, metal parts are blasted and cleaned and protected by a phosphoric bath.

SEMI-FINISHED STOCK

We produce in quantities. Semi-finished parts are painted and assembled to order, so we can deliver quickly.

POWDER COATING

In order to achieve an absolutely even and stable coating, we work with an electrostatic powder coating.

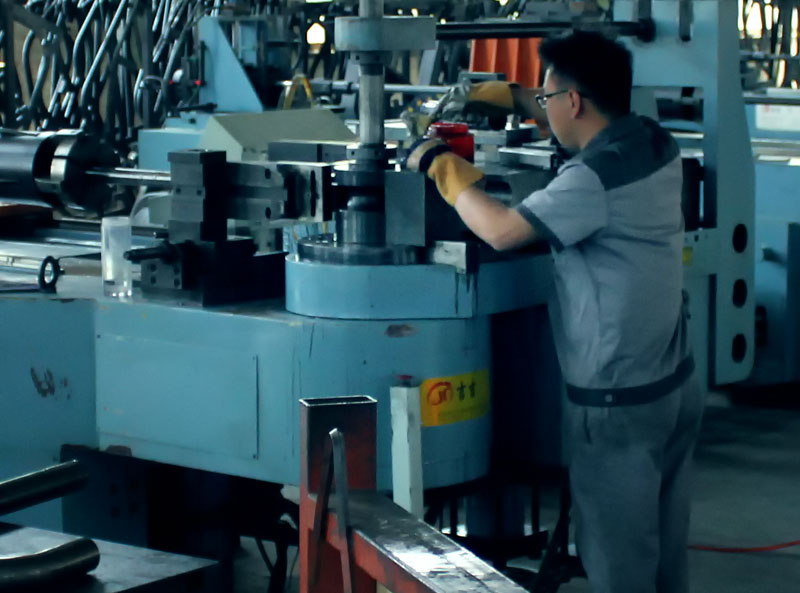

TUBE BENDING

We use mandrel bending machines to achieve precise bends – for maximum precision and quality.

CNC TURNING

All turned parts are manufactured in our factory.

UPHOLSTERY

Our in-house upholstery shop produces precision seats and upholstery.

WEIGHT PACKAGES

We even produce the weight stacks in-house.

SHABLES

All parts are manufactured in welding templates to ensure a high degree of fitting accuracy.

SHOWROOM

DHZ Fitness presents its equipment in 9 showrooms in China alone.

QUALITY

We place the highest value on quality in our production. DHZ Fitness is proud to be one of the top manufacturers in the world.

DEVELOPMENT

Our development department works with the latest CAD software to constantly expand and improve our product range.

TEST LABORATORY

Our ISO 9001 quality management system requires regular testing by our in-house laboratory.

ASSEMBLY

Final assembly is carried out on belts. Accessories such as screws etc. are pre-assembled.

LASER CUTTING

We work with CNC lasers to produce the three-dimensional frame parts and panels precisely and to place holes for bushings with pinpoint accuracy.

ROBOT WELDING

Robots are precise, produce clean, even weld seams and don’t forget anything.

SANDBLASTING & PHOSPHORIC ACID BATH

For prevention and rust removal, metal parts are blasted and cleaned and protected by a phosphoric bath.

SEMI-FINISHED STOCK

We produce in quantities. Semi-finished parts are painted and assembled to order, so we can deliver quickly.

POWDER COATING

In order to achieve an absolutely even and stable coating, we work with an electrostatic powder coating.

TUBE BENDING

We use mandrel bending machines to achieve precise bends – for maximum precision and quality.

CNC TURNING

All turned parts are manufactured in our factory.

UPHOLSTERY

Our in-house upholstery shop produces precision seats and upholstery.

WEIGHT PACKAGES

We even produce the weight stacks in-house.

SHABLES

All parts are manufactured in welding templates to ensure a high degree of fitting accuracy.

SHOWROOM

DHZ Fitness presents its equipment in 9 showrooms in China alone.

QUALITY

We place the highest value on quality in our production. DHZ Fitness is proud to be one of the top manufacturers in the world.

DEVELOPMENT

Our development department works with the latest CAD software to constantly expand and improve our product range.

TEST LABORATORY

Our ISO 9001 quality management system requires regular testing by our in-house laboratory.

ASSEMBLY

Final assembly is carried out on belts. Accessories such as screws etc. are pre-assembled.

LASER CUTTING

We work with CNC lasers to produce the three-dimensional frame parts and panels precisely and to place holes for bushings with pinpoint accuracy.

ROBOT WELDING

Robots are precise, produce clean, even weld seams and don’t forget anything.

SANDBLASTING & PHOSPHORIC ACID BATH

For prevention and rust removal, metal parts are blasted and cleaned and protected by a phosphoric bath.

SEMI-FINISHED STOCK

We produce in quantities. Semi-finished parts are painted and assembled to order, so we can deliver quickly.

POWDER COATING

In order to achieve an absolutely even and stable coating, we work with an electrostatic powder coating.

TUBE BENDING

We use mandrel bending machines to achieve precise bends – for maximum precision and quality.

CNC TURNING

All turned parts are manufactured in our factory.

UPHOLSTERY

Our in-house upholstery shop produces precision seats and upholstery.

WEIGHT PACKAGES

We even produce the weight stacks in-house.

SHABLES

All parts are manufactured in welding templates to ensure a high degree of fitting accuracy.

SHOWROOM

DHZ Fitness presents its equipment in 9 showrooms in China alone.

We are certified.

Top quality that is tested.

DIN ISO 9001

DIN EN20957/2

CE MARKING

Numbers that we are proud of.

0

Employees

0 m²

Production area

> 0

Equipped studios

0

Employees

0 m²

Production area

> 0

Equipped studios